Importance of TMT Rebar in Construction

Appropriate for Earthquake-Prone Areas

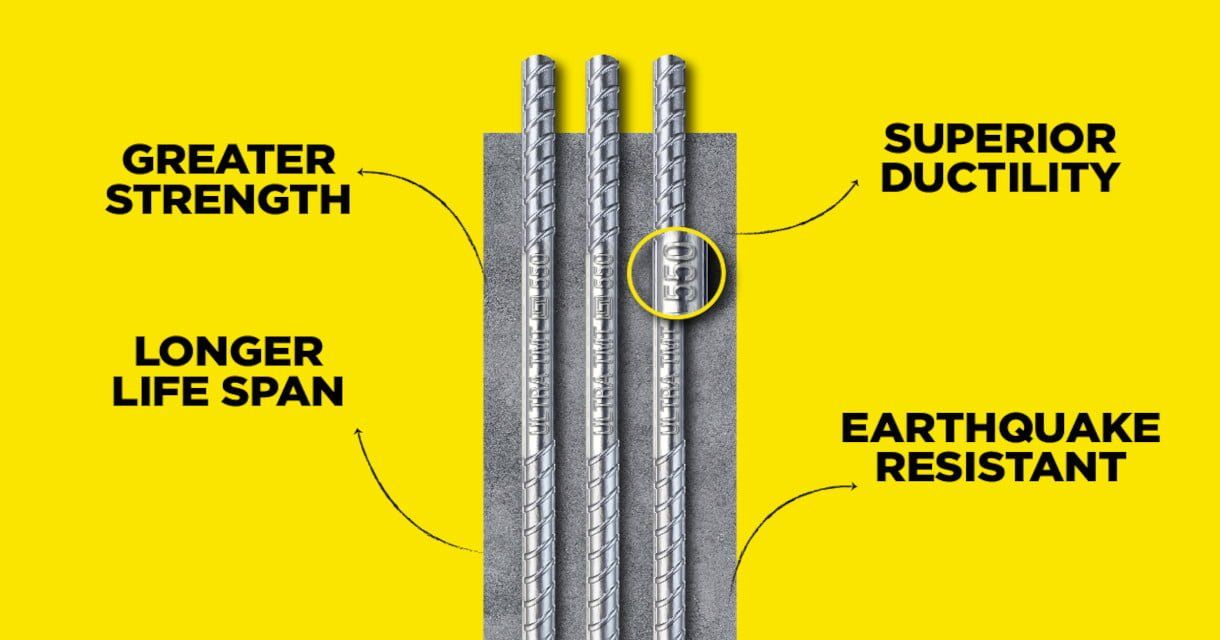

It is essential to use high-grade TMT bars as it maintains a perfect balance between strength and flexibility. The bars can hold the structure during any natural calamity and keep it uprooted with the required tensile strength. The bars, with their soft inner core and hard outer shell, help the buildings stand stable during a catastrophe. Due to the feature, the bars can endure the dynamic and seismic pressure created by earthquakes and other natural disasters. The high fatigue-resistance quality of the TMT bars resists the seismic load with its high ductility. Hence, the bars are best suited for construction projects in the earthquake and other natural disaster prone areas.

Strength and ductility are features of TMT Bars.

The TMT bars’ exceptional ductility and bendability is one of their distinguishing features. The TMT bars are a great option for a variety of building projects due to their strong stability. Further strength is provided by the bars’ distinctive design, which also attaches them more firmly to the concrete structure. As a result, the builders are able to produce pre-welded meshes, doing away with the requirement for manual binding. The bars’ exceptional degree of flexibility prevents them from cracking even after being bent 180 degrees.

The TMT bars are resistant to both fire and corrosion.

The anti-rust qualities of the steel bars are a result of the TMT bars production process. Long-term corrosion of steel is brought on by coarse carbides. The bars include rust-resistant substances like phosphorus, copper, carbon, and sulphur. A construction material had to be created immediately in the 19th century in order to increase the strength and durability of the buildings. The cost-effective TMT bars provide numerous technical and building benefits. The steel bars that have undergone thermomechanical treatment must be used in construction. Costs for maintenance and repairs are reduced by the corrosion-resistance characteristics and improved bonding.

Heat resistance is yet another important component. The building’s basic structure can withstand the heat in the event of a fire accident, preventing more casualties. Bridges, flyovers, dams, and other domestic and public infrastructure projects are made possible by the bars. The bars have a strong thermal stability and can withstand temperatures of up to 600 degrees Celsius.

The TMT bars do not melt rapidly in the event that the structures experience a devastating fire disaster, making the structure stand solid.

Solid Bonding Strength features TMT Bars

Adhesion and friction are two essential elements that make the TMT bars stronger. The bars become closely bound all around as a result of the cement’s shrinking. To solidify the structure, a particular water-to-cement ratio is necessary. The link between the TMT bars and the cement surface determines the strength. The binding strength is increased by the addition of materials like methylcellulose or latex.

Easy to Work With on the Construction Site

Thermal mechanically treated steel bars’ high ductility and bendability make labour on the construction site more convenient. The bars are easier to construct and move because of their flexibility and light weight. The bars’ small weight makes it simple for the workers to move them from one side to the other without getting hurt. That is one of the key characteristics that makes TMT bars so practical and a viable alternative for use on building sites.

TMT Bar: An Economical Building Option

World-wide, steel is a crucial component of building. High-strength steel bars are in extremely high demand due to the expansion of construction operations. The cost of steel has gone up due to the rise in demand for steel-based products. Because of their thickness and strength, TMT bars are reasonably priced. Due to the bars’ special qualities, such as high elongation, less steel is used during construction, which lowers the cost. If you think of the fee as a one-time payment, it could seem exorbitant. Nevertheless, if you factor in the whole cost over your entire life, it might not seem like such a steep price to pay. You won’t need to make any long-term adjustments or replacements to your building site once you’ve purchased TMT bars from the top TMT bars suppliers to create your project. The bars have a lifespan of more than a century, so the cost was justified.

To Sum it Up,

In conclusion, because of their high strength, oxidation resistance, ductility, weldability, and fire resistance, TMT steel bars are a crucial component in the construction industry. They are a common option for both builders and architects and are utilised in a wide range of construction projects, from straightforward buildings to intricate constructions. TMT steel bars are likely to continue to play a significant role in the building industry for many years to come as construction methods and materials continue to advance.

Importance of TMT Rebar in Construction

TMT bars have high tensile strength, which makes them ideal for use in construction. They are able to withstand heavy loads and are also resistant to earthquakes and other natural calamities.

TMT bars are highly resistant to corrosion, thanks to their unique manufacturing process. This makes them ideal for use in areas that are exposed to moisture, humidity, or salty air.

TMT bars have high ductility, which means they can be easily molded into different shapes and sizes. This makes them ideal for use in a wide range of construction projects, from simple buildings to complex structures.

TMT bars are easy to weld, which makes them ideal for use in construction projects that require a lot of welding.

TMT bars are highly resistant to fire, which makes them ideal for use in buildings that need to meet fire safety regulations.

REBAR

REBAR

CEMENT

CEMENT

PLUMBING

PLUMBING

ELECTRICAL

ELECTRICAL

SANITARY

SANITARY

BATHWARE

BATHWARE

PAINT

PAINT

FLOORING

FLOORING

HARDWARE

HARDWARE

Informative article , thanks for sharing